What types of solar cells are there, and how do you choose one?

Classification of solar panels

1. Monocrystalline silicon solar panel

Monocrystalline silicon solar panels are arguably the most popular and widely used type of solar panel on the market today.

The core of this technology is monocrystalline silicon. A small silicon crystal is placed in a high-temperature, pure silicon molten pool. It is then slowly pulled into a large, high-purity monocrystalline silicon crystal, which has a specific name: a silicon ingot. Finally, this thick silicon ingot is sliced into thin silicon wafers, which are then used to make our solar panels.

What makes it so powerful?

Because it is monocrystalline, electrons have more space to move within it, allowing for smoother movement.

This means extremely high efficiency; it is more efficient than another common type of solar panel, polycrystalline silicon. Its efficiency typically reaches between 21% and 24%, making it a top performer among solar panels.

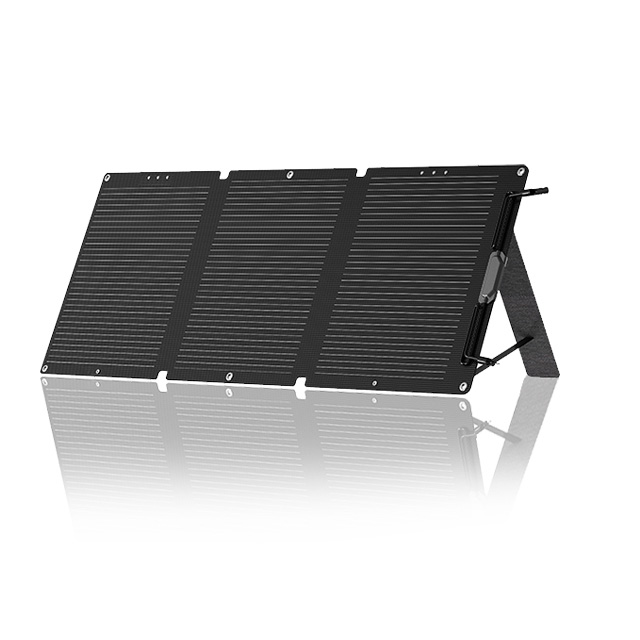

Our 120w portable solar panel with integrated high density monocrystalline solar panel with ETFE polymer integrated housing and IPX4 waterproof.

| Parameter | Specification / Value |

| Model | 120W |

| Solar Cell | Monocrystalline |

| Max Output | 19.44V 6.17A (120W Max) |

| Interface | MC4 |

| Waterproof Grade | IP65 |

| Craftsmanship | One-piece molding |

| Folded Size | 505 x 423 x 25 mm |

| Unfolded Size | 1548 x 505 x 4 mm |

| Weight | 6 KG |

2. Polycrystalline silicon solar panel

Polycrystalline solar panels are somewhat similar to monocrystalline silicon solar panels, as they are also made from silicon. However, their cooling processes differ. Polycrystalline solar panels cool to form many small crystals, unlike monocrystalline silicon which has a single large crystal. Because of this manufacturing process, polycrystalline solar panels generally appear bluish.

However, the silicon used is not as pure, and the structure is not as refined as monocrystalline panels. Therefore, in terms of converting sunlight into electricity and in terms of power generation efficiency in the same space, polycrystalline panels are less efficient, typically around 16% to 20%. Furthermore, they are not very heat-resistant; in areas with consistently hot climates, polycrystalline solar panels are not recommended.

3. Thin-film solar panel

Thin-film solar panels are made by layering a very thin layer of photovoltaic material onto a solid surface like glass. What kinds of photovoltaic materials are used? There's amorphous silicon (a-Si); copper indium gallium selenide (CIGS); and cadmium telluride (CdTe).

Each material produces a slightly different type of solar panel, but they all fall under the broad category of thin-film solar cells. A key advantage of thin-film solar panels is their flexibility; they don't require a solar panel support frame. Because of this, they are much lighter than other panels and much easier to install.

Unlike standard-sized crystalline silicon solar panels, which typically come in sizes with 60, 72, or 96 cells, thin-film solar panels can be customized to your specific needs. However, they also have a drawback: their efficiency is lower than that of standard silicon solar panels.